- Grinding & Dispersing Systems,

Designed for Your Profits

- Home

- Products

- Mixing & Deaerating

- Planetary Mixing Machine, XJ

Planetary Mixing Machine, XJ

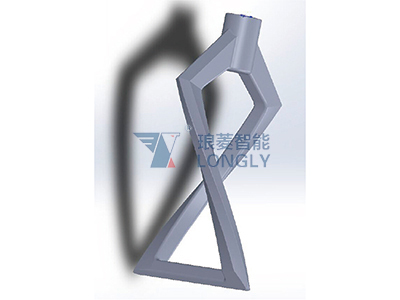

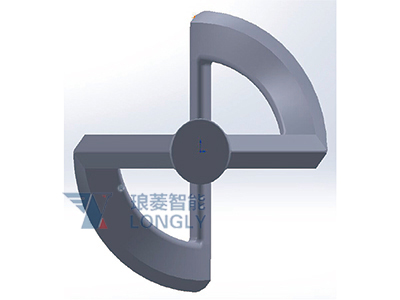

Planetary mixing machine is used to accomplish mixing and dispersing tasks within a short time by using versatile mixing tools. The planetary mixer is configured with two identical blades that rotate on their own axes while orbiting the mixing vessel. Meanwhile scraping blade rotates continuously to transfer the materials closer to the mixing blades. At the same time, two saw-tooth disperser blades revolve at a high speed to implement dispersing and stirring in the mixing vessel.

- Temperature sensor is located at bottom of mixing vessel, reliably providing precise temperature measurements of materials;

- Mixing blades of various shapes and sizes are changeable;

- Mixing tools are manufactured through precision casting process, will not induce elastic deformation, suitable for high load operation;

- Rotating speed is adjustable according to specific needs;

| Model | Tank Parameter | Motor Power (kW) | Speed (rpm) | Weight | Dimension | |||||

| Net Volume | Designed Volume | Barrel Size (mm) | Revolution Motor | Dispersing Motor | Revolution Speed | Stirring Speed | Dispersing Speed | kg | LxWxH(mm) | |

| LV-5L | 5L | 7.85L | Ø250x150 | 1.5 | 1.5 | 0-45 | 0-90 | 0-8000 | 415 | 1200x700x1800 |

| LV-10L | 10L | 14L | Ø300x200 | 2.2 | 2.2 | 0-43 | 0-84 | 0-6000 | 550 | 1300x800x1800 |

| LV-30L | 30L | 44L | Ø400x350 | 3 | 4 | 0-42 | 0-77 | 0-5000 | 900 | 1630x900x1950 |

| LV-60L | 60L | 88L | Ø500x450 | 5.5 | 7.5 | 0-38 | 0-53 | 0-4000 | 1700 | 1200x700x1800 |

| LV-100L | 100L | 149L | Ø650x450 | 7.5 | 11 | 0-36 | 0-46 | 0-3400 | 2700 | 1800x1100x2300 |

| LV-200L | 200L | 287L | Ø750x650 | 15 | 22 | 0-33 | 0-42 | 0-2750 | 4200 | 2400x1600x2900 |

| LV-300L | 300L | 369L | Ø850x650 | 22 | 30 | 0-32 | 0-44 | 0-2200 | 7200 | 3300x1300x3100 |

| LV-650L | 650L | 807L | Ø1100x850 | 45 | 55 | 0-28 | 0-42 | 0-1750 | 10500 | 3800x1600x4000 |

| LV-1000L | 1000L | 1327L | Ø1300x1000 | 75 | 90 | 0-20 | 0-36 | 0-1500 | 13000 | 4170x1800x4780 |

| LV-1500L | 1500L | 2120L | Ø1500x1200 | 75 | 90 | 0-13 | 0-35 | 0-1200 | 17500 | 4430x2050x4850 |

- Lithium Ion Battery Slurry (Polymer and Solvent)

- Adhesives

- Mold Glue

- Silicone Sealant

- Polyurethane Sealant

- Anaerobic Adhesives

- Inks

- Pigments

- Cosmetics

- Ointments

- Chemicals

- Pharmaceuticals

- Food Processing

- Pesticides

- Many Others