- Grinding & Dispersing Systems,

Designed for Your Profits

- Home

- Products

- Systems and Plants

- Complete Grinding System

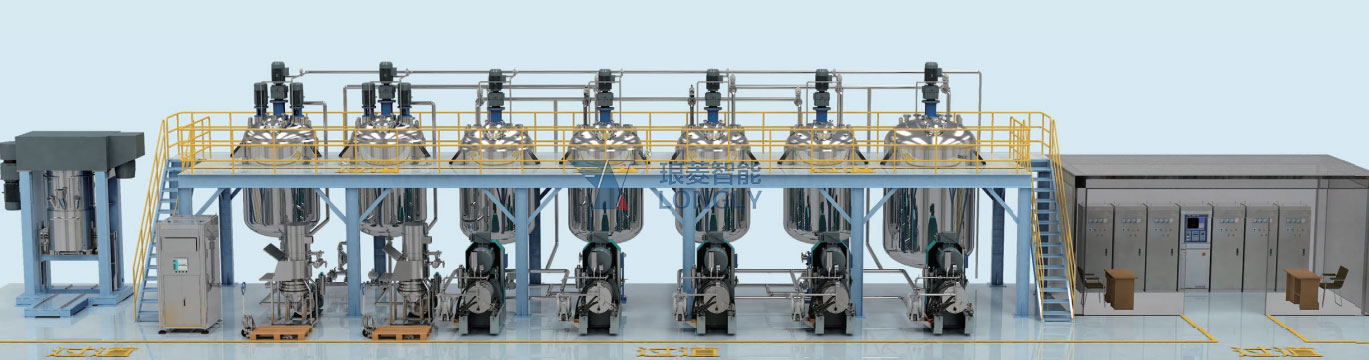

Complete Grinding System

Relying on our knowledge and expertise in the field of wet grinding in terms of machines and plant engineering, we at Longly are capable of providing complete solution tailored to your needs of laboratory and manufacturing plant applications.

We deliver services for over 40 industries, including battery slurry, lithium iron phosphate, iron oxide, silicon carbon anode material, graphene, ceramic ink, nano materials, electronic ceramics, new energy, paint, coating, ink, etc.

- The complete system consists of raw material storage, material feeding and dosing, conveying, dispersing and grinding, filtering and filling, final product storage, measuring, PLC controlling, electrical system and steel platform.

- The raw materials are independently stored in the storage area. Appropriate storage containers are used in accordance with the material characteristics, and reasonable arrangement and protection measures are also guaranteed.

- Feeding and dosing methods are selected per specific requests, it is possible to automatically accomplish processes of feeding, dosing, measuring and accuracy control, and can ensure contamination-free and dust-free production.

- During the dispersing and mixing processes, it allows to perform control of formula adding, pump conveying, quality inspecting, process monitoring, strictly adhering the requirements of dispersing and grinding fineness.

- Filtering and filling system is composed of filtering unit, filling unit and final product tank stacking unit, which are fully automatic controlled and managed, greatly improving production efficiency and reducing errors caused by human factors.

- Characterized by digitalization, standardization and intelligence;

- Suitable for batch production, and can be configured according to the throughput and process;

- Fully automatic systems are available per customers’ request, such as automatic dosing, inline inspection, automatic control of valve, computer remote control and PLC human-machine interface, facilitating production management due to less human factors;

- Sensors and meters have features of high precision, excellent stability, quick response and long service life. They can provide precise measurements of dosing and mixing by displaying through touch screen and computer monitor, efficiently preventing the dosing errors caused by manual operation;

- PLC system has high stability and reliability, and it is easy to carry out maintenance and upgrading;

- Not only saves time, labor and energy, but also is eco-friendly;

- Industrial Paint

- Automotive Paint

- Natural Stone Paint

- Water-Based Polyurethane

- Furniture Paint

- Ink

- Water-Based Paint

- Resin

- Latex Paint

1. The entire production line is configured with PLC, touch screen and

computer control to accomplish automatic and manual operation modes.

2. The status of system will be displayed on the computer monitor.

3. The required data can be set according to the actual needs and be

permanently saved. After the data is set, there is no need to repeat the

setting.

4. In automatic mode, any unit being maintained or suspended will not

affect the entire production process, the continuous production can be

ensured without downtime.

5. The limits of rotating speed, temperature and pressure of the machine

can be set according to the demand, if any value exceeds the limit,

alarm will be activated to stop the operation, effectively protecting

the machine from damage.

6. System faults will be displayed on the monitor, easy to troubleshoot

the problems.

- Beside the need of manual opening of raw material, other processes include dosing, weighing, feeding, stirring, rough grinding, fine grinding, filtration, de-ironing and conveying are all accomplished through automatic or manual programming controlled by computer, thus avoiding errors caused by human factors and efficiently improving the stability of batch production.

- The data will be collected 10 times per minute by computer system, and can be stored in the system for 3 months. The formula of product from each batch can be retrieved and is possible to analysis the production data for the aims of process improving and productivity increasing.

- The pressure sensor is equipped at outlet of conveying pump to real-time monitoring of the outlet pressure, alarm will be activated when the pressure is too high or too low, efficiently protecting the system from damage.

- The system runs automatically requiring one key to start.

- The main operating parameters of the system including temperature, pressure and weight will be automatically recorded in the computer, which can be easily accessed by user at any time.

- Remote system accessing function can be configured, user can check the production and equipment operation status through personal mobile phone or computer.

- The control system has multiple access rights for assigning to operating personnel, maintenance personnel, and management personnel, preventing unauthorized operations.