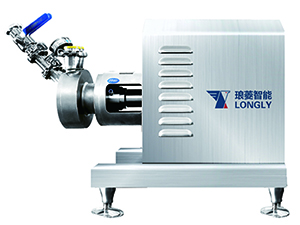

- Grinding & Dispersing Systems,

Designed for Your Profits

- Home

- Products

- Mixing & Deaerating

- Mixing Tank

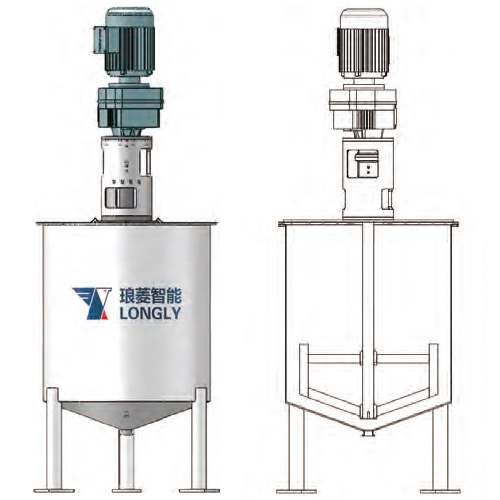

Mixing Tank

High-speed mixer is designed for mixing, dissolving and dispersing of two liquids or liquid-solid in various industries including coatings, dyes, pigments, papermaking, adhesives and other chemical and industrial applications.

- Suitable for almost any of two liquids or liquid-solid mixing, dissolving and dispersing;

- Stable operation, low noise and easy to clean;

- Fast dissolving and particle size reduction;

- Available in three structures, i.e. open, enclosed and completely enclosed (vacuum); Vessel can be custom made into single walled, double walled with cooling jacket, and/or insulation layer;

- Coatings

- Paints

- Inks

- Papermaking

- Adhesives

- Pharmaceutical

- Chemical

- Many Others

| Model | GF-050 | GF-100 | GF-200 | GF-300 | GF-500 | GF-1000 | GF-1500 |

| Rated Capacity (L) | 70 | 120 | 250 | 370 | 600 | 1200 | 1800 |

| Inner Tank Dimension (mm) | Ø430x490 | Ø520x570 | Ø650x720 | Ø750x800 | Ø900x900 | Ø1100x1200 | Ø1300x1250 |

| Vessel Structure | Single layer / double layer / triple layer | ||||||

| Vessel Bottom | Conical bottom / dished bottom | ||||||

| Vessel Cover | Double-hinged cover / flat cover / dished cover | ||||||

| Motor Power (kW) | 1.1 | 2.2 | 3 | 4 | 5.5 | 11 | 15 |

| Rotating speed (rpm) | 0-1430 | 0-1430 | 0-1440 | 0-1440 | 0-1450 | 0-1450 | 0-1450 |

| Mixing Tools | Dispersing disc | Dispersing disc | Dispersing disc | Dispersing disc | Dispersing disc | Dispersing disc | Dispersing disc |

| Mixing Tool Diameter (mm) | Ø120 | Ø150 | Ø150 | Ø200 | Ø250 | Ø300 | Ø320 |

| Weight (kg) | 150 | 200 | 250 | 300 | 400 | 800 | 1200 |

| Overall Dimension (mm) | 600x600x1200 | 600x600x1200 | 750x750x1200 | 850x850x1600 | 1100x1100x2200 | 1300x1300x2500 | 1500x1500x2800 |

Low-speed mixer is a mixing vessel that efficiently mixes high viscosity fluids, and also suitable for temporary storing of materials during transferring to prevent stratification and sedimentation of materials.

- Available in three structures, i.e. open, enclosed and completely enclosed (vacuum);

- Vessel can be custom made into single walled, double walled with cooling jacket, and/or insulation layer;

- Coatings

- Paints

- Inks

- Papermaking

- Adhesives

- Pharmaceutical

- Chemical

- Many Others

| Model | GB-050 | GB-100 | GB-200 | GB-300 | GB-500 | GB-1000 | GB-1500 |

| Rated Capacity (L) | 70 | 120 | 250 | 370 | 600 | 1200 | 1800 |

| Inner Tank Dimension (mm) | Ø430x490 | Ø520x570 | Ø650x720 | Ø750x800 | Ø900x900 | Ø1100x1200 | Ø1300x1250 |

| Vessel Structure | Single layer / double layer / triple layer | ||||||

| Vessel Bottom | Conical bottom / dished bottom | ||||||

| Vessel Cover | Double-hinged cover / flat cover / dished cover | ||||||

| Motor Power (kW) | 0.55 | 0.75 | 1.1 | 1.5 | 2.2 | 4 | 5.5 |

| Rotating speed (rpm) | 0-60 | 0-60 | 0-60 | 0-60 | 0-60 | 0-60 | 0-60 |

| Mixing Tools | Anchor impeller | Anchor impeller | Anchor impeller | Anchor impeller | Anchor impeller | Anchor impeller | Anchor impeller |

| Mixing Tool Diameter (mm) | Ø380 | Ø470 | Ø600 | Ø700 | Ø840 | Ø900 | Ø1400 |

| Weight (kg) | 170 | 220 | 280 | 350 | 450 | 1000 | 1500 |

| Overall Dimension (mm) | 600x600x1200 | 600x600x1500 | 750x750x1400 | 850x850x1600 | 1100x1100x2200 | 1300x1300x2800 | 1500x1500x3000 |

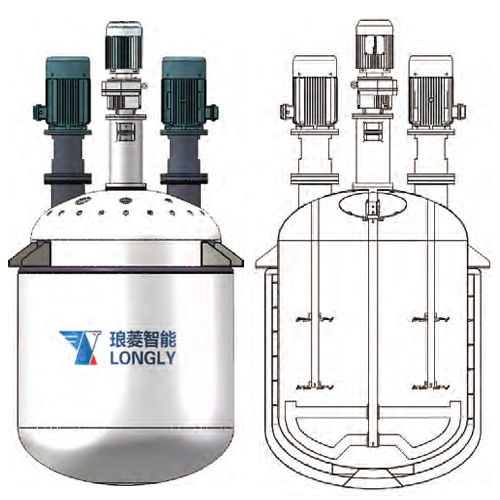

This mix and dispersion system is a multi-shaft mixer that provides high shear to mix and disperse medium and high viscosity materials, suitable for various powders and liquids. It can be custom manufactured with mechanical seal and enclosed structure for vacuum operation. Vessel body can be provided in double walled structure with cooling jacket, and/or insulation layer.

- Coatings

- Paints

- Inks

- Papermaking

- Adhesives

- Pharmaceutical

- Chemical

- Many Others

| Model | GD-1000 | GD-1500 | GD-2000 | GD-3000 | GD-5000 |

| Rated Capacity (L) | 1380 | 1900 | 2500 | 3600 | 6000 |

| Inner Tank Dimension (mm) | Ø1200x1000 | Ø1300x1200 | Ø1400x1400 | Ø1600x1500 | Ø1800x2000 |

| Vessel Structure | Double layer / triple layer | ||||

| Vessel Bottom | Dished bottom | ||||

| Vessel Cover | Double-hinged cover / dished cover | ||||

| Mixing Power (kW) | 4 | 5.5 | 5.5 | 7.5 | 11 |

| Mixing Speed (rpm) | 0-60 | 0-60 | 0-40 | 0-40 | 0-40 |

| Dispersion Power (kW) | 5.5+5.5 | 7.5+7.5 | 11+11 | 15+15 | 15+15 |

| Dispersion Rotating Speed (rpm) | 1450 | 1450 | 1450 | 1450 | 1450 |

| Mixing Tools | 1 anchor impeller, 4 dispersing discs | ||||

| Weight (kg) | 1800 | 2000 | 2500 | 3000 | 4500 |

| Overall Dimension (mm) | 1550x1550x3000 | 1650x1650x3200 | 1700x1700x3500 | 1900x1900x4000 | 2100x2100x4500 |

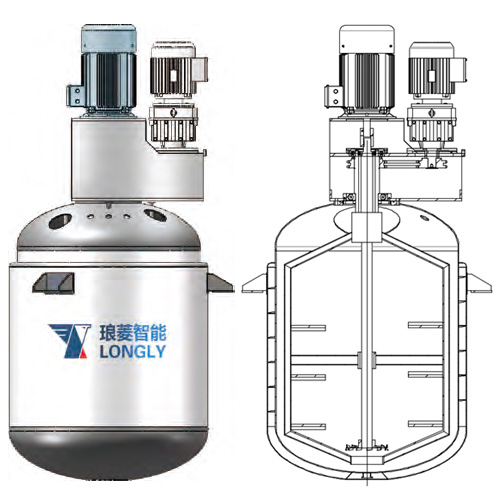

Dual shaft mixer consists of low-speed gate impeller and high speed dispersing discs that are moved in concentric rotation to stir and disperse medium and high viscosity materials. With the rotation of the gate impeller, materials are transferred toward the center of the vessel and then dispersed by dispersing discs rapidly, thus ensuring an excellent efficiency of dispersing, dissolving and mixing. The dual shaft mixer can be custom manufactured with mechanical seal and enclosed structure for vacuum operation. Vessel body can be provided in double walled structure with cooling jacke, and/or insulation layer.

- Coatings

- Paints

- Inks

- Papermaking

- Adhesives

- Pharmaceutical

- Chemical

- Many Others

| Model | GS-200 | GS-300 | GS-500 | GS-1000 | GS-1500 | GS-2000 |

| Rated Capacity (L) | 250 | 370 | 600 | 1380 | 1900 | 2500 |

| Inner Tank Dimension (mm) | Ø650x700 | Ø750x800 | Ø900x900 | Ø1100x1000 | Ø1300x1200 | Ø1400x1400 |

| Vessel Structure | Double layer / triple layer | |||||

| Vessel Bottom | Dished bottom | |||||

| Vessel Cover | Double-hinged cover / dished cover | |||||

| Mixing Power (kW) | 2.2 | 3 | 3 | 4 | 5.5 | 7.5 |

| Mixing Speed (rpm) | 0-60 | 0-60 | 0-50 | 0-60 | 0-50 | 0-40 |

| Dispersion Power (kW) | 3 | 4 | 5.5 | 11 | 15 | 22 |

| Dispersion Rotating Speed (rpm) | 1450 | 1450 | 1450 | 1450 | 1450 | 1450 |

| Mixing Tools | 1 gate impeller, 4 dispersing discs | |||||

| Weight (kg) | 500 | 800 | 1200 | 1800 | 2000 | 2500 |

| Overall Dimension (mm) | 800x800x1850 | 900x900x2000 | 1000x1000x2500 | 1550x1550x3000 | 1650x1650x3200 | 1750x1750x3500 |