- Grinding & Dispersing Systems,

Designed for Your Profits

- Home

- Products

- Mixing & Deaerating

- Vacuum Deaerator, LTP

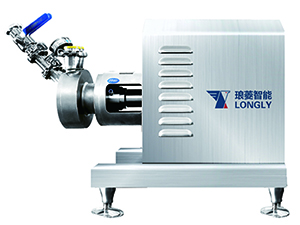

Vacuum Deaerator, LTP

Vacuum deaerator of negative pressure deaeration system is primarily used to remove entrained gasses from liquids of various viscosities. Vacuum deaerator works on the basis of VTR principle (vacuum thin-film rotary process), so that micronized gas and air pockets can be efficiently eliminated from fluids with a vast range of viscosity. Vacuum deaerator can be widely used in automatic production lines.

- Utilizing VTR principle (vacuum thin-film rotary process) achieves inline production;

- Short gas removal time, high efficiency;

- All parts in contact with liquid are made of corrosion-resistant stainless steel, perfluoroelastomer, PTFE and other contamination-free materials;

- Processing volume can be adjusted by controlling rotating speed of drive, to achieve easy switching between fully automated, semi-automatic, and manual modes;

- Modular structure, easy to clean and operate;

- No need to add any agent, greatly reducing material cost and retaining material characteristics;

- MES ports is available for connection with central control system, realizing centralized control and monitoring;

- Battery Slurry

- New Energy

- Chemical

- Inks

- Coatings

- Food Processing

- Pharmaceutical

- Cosmetics

| Model | Rotating speed (rpm) | Power (kW) | Throughput (L/H) (varies among material viscosities) | Applicable Viscosity (mPa.s) |

| LTP-50 | 0-1465 | 5.5 | 0-200 | 0-15000 |

| LTP-100 | 0-1470 | 11 | 0-700 | 0-15000 |

| LTP-200 | 0-1470 | 18.5 | 0-1500 | 0-15000 |